Mechanical Vapour Recompression

Mechanical Vapour Recompression (MVR) reduces vapour consumption, replaced by a source of electrical energy, resulting in a very low operating cost compared to a multiple effect operation.

Home > Technologies > Evaporation > Mechanical Vapor Recompression (MVR)

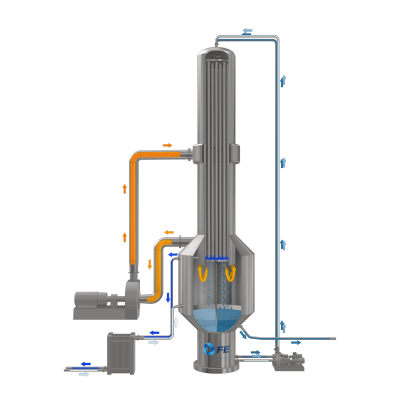

The vapour produced by the evaporator is sent to a MVR installation, to be compressed and heated up.

It is then resent to the evaporator to the outside of the tubes to be used as a heating steam. In this process, the evaporator is also used as the condenser for the vapour evaporation.

The main advantage of the Mechanical Vapour Recompression technology is its low operating costs.

Energy consumption per tonne of evaporated water:

- MVR: ~ 15 kW.h / hr electric

- Single effect: ~ 630 kW thermal

- Triple effect: ~ 230 kW thermal

- Six fold effect: ~ 115 kW thermal

Cost reduction

- Vapour consumption almost zero

- Low consumption of cooling water

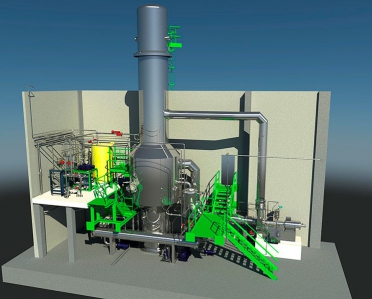

- More compact layout, compared to a multiple effect evaporator (an MVR evaporator is composed of a single evaporation body and a compressor)

Simplicity, responsiveness and flexibility of operation

The compressor is driven by a frequency inverter, which enables the implementation capacity to be finely and quickly adjusted from 30% to 100% of the maximum capacity.

Adaptation to production constraints

The MVR technology makes it possible for several compressors to be used in series in order to respond to constraints (significant boiling delay, decrease in exchange surface, etc).

Reliability

When correctly sized and installed, RMV’s processes are highly reliable. We have been using this technology for over 20 years, and maintenance costs are extremely low for the compressors we use.

In order to optimize this reliability, FE by< 0 > has developed unique expertise:

- A largely sized separator, which allows maximum separation of evaporation vapour and avoids provoking product droplets in the MVR, in order to ensure the fan’s lifespan.

- Among our facilities, in addition to the separator, a vapour scrubber cleans the evaporation vapours and helps deconcentrate any remaining product droplets to preserve the blower mechanism. It also helps in countering foaming.

- On the outlet of the scrubber, a mist eliminator prevents possible droplets

- Many additional securities to monitor and ensure the proper functioning of the installation: levels, temperatures, vibrations, etc.