Transformation from multiple effect to MVR

One of the main energy optimisations is the transformation of an existing single effect or multiple effect unit into Mechanical Vapour Compression (MVC).

Home > Technologies > Energy efficiency > Transformation from multiple effect to MVR

The case of multiple effect

On a multi-effect unit, the evaporator operates at a different pressure.

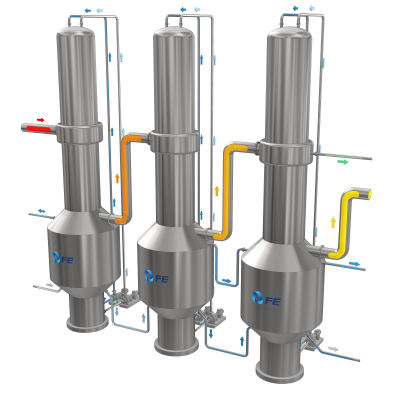

To transform the evaporator into MVC, all the separators are connected to collect the evaporation vapour from each evaporation body, in order to direct them to a vapour scrubber and then to one or more MVC units, depending on the installation, to maintain the production capacity.

The compressed vapours at the MVC outlet can then be sent to the evaporator radiators to be reused.

It is possible to keep the existing multiple effect operation by using a set of valves, if the MVC is not available.

High-temperature heat pump: a pilot project with EDF

France Evaporation has jointly developed with EDF, a high temperature heat pump which includes an MVC compressing vapour at 80°C to increase to 120°C.

This compressor will soon be installed on an industrial site for validation in the long term. The compressor’s inlet temperature and capacity will subsequently be adjusted to meet different needs.

France Evaporation is working on various applications of Mechanical Vapour Compression (MVC).

- Recovery of vapour at the exit of a multiple effect and return leading the multiple effect (without altering the existing sheath network)

- Vapour compression on ethanol columns

- Compression on benders