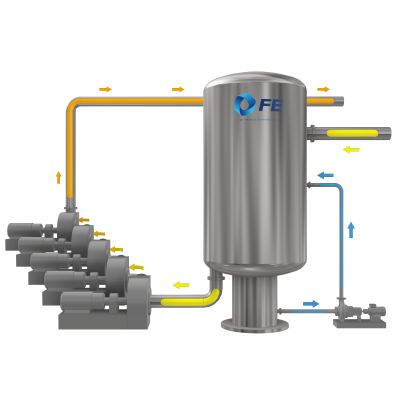

Mechanical Vapour Recompression (MVR)

Mechanical compression raises the temperature and vapour pressure, allowing its reuse and a significant improvement in the energy performance of a facility.

Home > Industries > Decarbonization > Mechanical vapor Recompression (MVR)

Multiple applications

MVR raises the temperature and pressure of “waste” vapors so they can be reused as a heat source for the process. The result: significant energy savings, reduced CO₂ emissions, and high reliability for demanding processes. FE designs and integrates single- and multi-stage (up to 15) systems that are instrumented, secure, and controlled for sustainable performance.

MVR captures low-pressure vapor (steam), mechanically compresses it using a centrifugal compressor to increase its pressure and temperature, and then reinjects it as a heating fluid. This allows heat that was previously lost to be recovered with high efficiency—even at very high temperatures (> 200 °C) depending on the application.

Technical advantages:

- Excellent efficiency (over 80%)

- Decarbonization: replacing fossil fuels with decarbonized electricity per kWh

- Wide temperature range (from 10°C to 200°C) and modularity (possibility of creating multiple steam outlets at different pressures)

- Pilotage fin par variateurs de fréquence et surveillance continue par nos équipes FE Service

Precise control via frequency converters and continuous monitoring by our FE Service teamsDomaines d’application

- Evaporation/crystallization (revamping or new units)

- Distillation columns (ammonia, solvents, alcohols, etc.)

- Steam drying (paper, agriculture, chemicals)

- Heat networks & site recovery (couplings, injection/extraction)

- Hybrid PAC + CMV systems when the source is “cold” (optimized CAPEX)

Performance & examples

Example in the sugar industry:

- 6 compressors

- Increase from 62°C to 105°C

- COP ≈ 6.3

- 22,000 tCO₂/year saved.